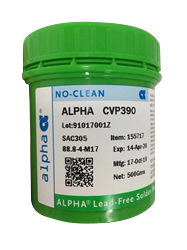

CVP390

ALPHA® CVP-390

NO-CLEAN, LEAD-FREE SOLDER PASTE ZERO-HALOGEN, LOW VOIDS, FINE FEATURE, EXCELLENT PIN TEST PERFORMANCE, SAC305, SAC405, & LOW AG CAPABLE

DESCRIPTION:

ALPHA CVP-390 is a lead-free, Zero-halogen no-clean solder paste designed for applications where

residue with excellent pin testing property and ability to pass JIS Copper Corrosion test are required.

This product is also designed to enable consistent fine pitch printing capability, down to 180m circle

printed with 100m thickness stencil. Its excellent print volume deposit repeatability also provides value

by reducing defects associated with print process variability. Additionally, ALPHA CVP-390 achieves

IPC7095 Class III voiding performance.

FEATURES & BENEFITS:

• Long Stencil Life: consistent performance for at least 8 hours of continuous printing without addition

of new paste

• Long, High Tack Force Life: ensures high pick-and-place yields, good self-alignment

• Wide Reflow Profile Window: allows best quality solderability of complicated, high density PWB

assemblies in both air and nitrogen reflow, using ramp and soak profiles, as high as 175 to 185°C

• Reduced Random Solder Ball Levels: minimizes rework and increases first time yield

• Excellent Coalescence and Wetting Performance: coalesced 180µm circle deposit, even at high

soak profile environment

• Excellent Solder Joint and Flux Residue Cosmetics: after reflow soldering, even using long/high

thermal soaking, without charring or burning

• Excellent Voiding Performance: Meets IPC7095 Class III Requirement

• Halogen Content: Zero Halogen, no halogen intentionally added

• Residue: Excellent Pin Testing property and Pass JIS Copper Corrosion Test

• Safe and Environmentally Friendly: Materials comply with RoHS and Halogen-free requirements

(see table below), as well as TOSCA & EINECS

PRODUCT INFORMATION:

Alloys: SAC105, SAC305, SAC405, SACX Plus 0307 SMT,

SACX Plus 0807 SMT, Innolot, Maxrel Plus, Sn99.3/Cu0.7, 90Sn10Sb,

95Sn5Sb, For other alloys, contact your local Alpha Sales Office

Powder Size: Type 3, Type 4, Type 4.5, Type 5, Type 6, & Type 7

Packaging Sizes: 500 gram jars, 10cc & 30cc syringe, 6” & 12” cartridges

Flux Gel: Flux gel is available in 10 and 30 cc syringes for rework applications

Lead Free: Complies with RoHS Directive 2011/65/EC

APPLICATION:

Formulated for both standard and fine pitch stencil printing, at print speeds of between 25mm/sec (1”/sec)

and 150mm/sec (6”/sec), with stencil thickness of 0.100mm (0.004”) to 0.150mm (0.006”), particularly when

used in conjunction with ALPHA Stencils. Blade pressures should be 0.21-0.36 kg/cm of blade (1.25 -1.5

Ibs/inch), depending upon the print speed. The higher the print speed employed, the higher the blade

pressure that is required. The reflow process window will give high soldering yield with good cosmetics and

minimized rework.

HALOGEN STATUS:

TECHNICAL DATA:

PHYSICAL PROPERTIES:

SAFETY:

SAFETY:

While the ALPHACVP-390 flux system is not considered toxic, its use in typical reflow will generate a small

amount of reaction and decomposition vapors. These vapors should be adequately exhausted from the

work area. Consult the SDS (available at www.AlphaAssembly.com) for all safety information.

STORAGE & HANDLING:

1. Refrigerate to guarantee stability

@ 0-10°C (32-50°F). When stored

under these conditions, the shelf

life of CVP-390 is 6 months.

2. Paste can be stored for 4 weeks

at room temperature up to

25°C(77°F) prior to use

3. When refrigerated, warm up

paste container to room

temperature for up to 4 hours.

Paste must be 19°C (66°F) before

processing. Verify paste

temperature with a thermometer to

ensure paste is at 19°C (66°F) or

greater before set up of printer.

4. Paste can be manually stirred

before use. A rotating/Centrifugal

force mixing operation is not

required. If a rotating/centrifugal

force mixing is used, 30 - 60

seconds at 300 RPM is adequate.

5. Do not remove worked paste

from stencil and mix with unused

paste in jar. This will alter the

rheology of unused paste.

6. These are starting

recommendations and all process

settings should be reviewed

independently.

PRINTING:

STENCIL: Recommend

ALPHA CUT, ALPHA

NICKEL-CUT, ALPHA

TETRABOND®

, or ALPHA

FORM stencils @

0.100mm - 0.150 mm (4-6

mil) thick for 0.4 - 0.5 mm

(0.016” or 0.020”) pitch.

Stencil design is subject to

many process variables.

Contact your local Alpha

stencil site for advice.

SQUEEGEE:

Metal (recommended)

PRESSURE: 0.21 - 0.36

kg/cm of blade (1.25 -2.0

Ibs/inch)

SPEED: 25 – 150 mm per

second (1 – 6 inches per

second).

PASTE ROLL: 1.5-2.0 cm

diameter and make

additions when roll reaches

1-cm (0.4”) diameter (min).

Max roll size will depend

upon blade.

STENCIL RELEASE

SPEED: 1 – 5 mm/sec.

LIFT HEIGHT: 8 – 14mm

(0.31- 0.55”)

REFLOW (see Fig. 1):

ATMOSPHERE: Clean-dry

air or nitrogen atmosphere.

PROFILE (SAC Alloys):

Straight Ramp: 0.7°C/sec &

1.3°C/sec ramp profiles, 45 - 90 TAL.

Soak: 155–175 °C, 60 to 100

sec soak profiles have been

determined to give optimal

results. If required, good

results are also achievable

with high soak temperature

profiles of 170 –185°C for 60

s. Typical peak temperature

is 235 to 245°C.

Note 1: Keeping the peak

temperature below 241ºC

may reduce the number and

size of BGA and QFN voids.

Note 2: Refer to component

and board supplier data for

thermal properties at elevated

temperatures. Lower peak

temperatures require longer

TAL for improved joint

cosmetics.

CLEANING:

ALPHA CVP-390 residue

is designed to remain on

the board after reflow. If

reflowed residue cleaning

is required, Vigon® A201

(in line cleaning), Vigon A

250 (Batch Cleaning) or

Vigon US (Ultrasonic

Cleaning) are

recommended. Vigon is a

registered trademark of

Zestron.

Misprints and stencil

cleaning may be done with

IPA, ALPHA SM-110E,

ALPHA SM-440, and

Bioact® SC-10E cleaners.

Bioact is a registered

trademark of Petroferm.

CONTACT INFORMATION:

CONTACT INFORMATION: