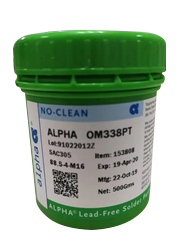

OM338PT

ALPHA® OM-338-PT

Fine Feature, Zero Halogen, Pin-Testable Lead-Free Solder Paste

DESCRIPTION:

ALPHA OM-338-PT is a lead-free, no-clean solder paste designed for a broad range of applications.

ALPHA OM-338-PT’s broad processing window is designed to minimize transition concerns from tin/lead

to lead free solder paste. This material is engineered to deliver the comparable performance to a tin lead

process. ALPHA OM-338-PT yields excellent print capability performance across various board designs;

particularly with ultra-fine feature repeatability (11 mil squares) and high “through-put” applications.

ALPHA OM-338-PT is formulated to offer increased in-circuit pin test yields versus OM-338 without

compromising electrical reliability.

Outstanding reflow process window delivers good soldering on CuOSP with excellent coalescence on a

broad range of deposit sizes, excellent random solder ball resistance and mid-chip solder ball

performance. ALPHA OM-338-PT is formulated to deliver excellent visual joint cosmetics. Additionally,

ALPHA OM-338-PT’s capability of IPC Class III for voiding and ROL0 IPC classifications ensures

maximum long-term product reliability.

*Although the appearance of these lead-free alloys will be different to that of tin-lead, with mechanical

reliability equal to or greater than with that of tin-lead or tin-lead-silver.

FEATURES & BENEFITS:

1.Maximizes reflow yield for lead-free processing, allowing full alloy coalescence at circular dimensions

as small as 0.225mm (0.011”) with 0.100mm (4mil) stencil thickness.

2.Excellent print consistency with high process capability index across all board designs.

3.Print speeds of up to 150mm/sec (6”/sec), enabling a fast print cycle time and a high throughput.

4.Wide reflow profile window with good solderability on various board / component finishes.

5.Excellent solder and flux cosmetics after reflow soldering

6.Reduction in random solderballing levels, minimizing rework and increasing first time yield

7.Excellent pin-test yield for single and double reflow.

8.Meets highest IPC 7095 voiding performance classification of Class III.

9.Excellent reliability properties, halide-free material

10.Compatible with either nitrogen or air reflow

PRODUCT INFORMATION:

Alloys: SAC305, SAC357, SAC387, SAC396, SAC405

SACX PlusTM 0307 SMT, & SACX PlusTM 0807 SMT

e1 alloys per JESD97 Classification

Powder Size: Type 3, Type 4, & Type 4.5

Residues: Approximately 5% by (w/w)

Packaging Sizes: 500 gram jars, 6” & 12” cartridges, DEK ProFlow® cassettes, and 10cc and

30cc dispense syringes

Flux Gel: ALPHA OM-338-PT Flux Gel is available in 10cc or 30cc syringes for rework

applications

Lead Free: Complies with RoHS Directive 2011/65/EU

NOTE 1: For other alloys, powder size and packaging sizes, contact your local Alpha Sales Office.

SAFETY:

While the ALPHA OM-338-PT flux system is not considered toxic, its use in typical reflow will generate a

small amount of reaction and decomposition vapors. These vapors should be adequately exhausted from

the work area. Consult the SDS for all safety information (www.AlphaAssembly.com).

ALPHA OM-338-PT should be stored in a refrigerator upon receipt at (1 to10)C, (34-50)°F. ALPHA OM-

338-PT should be permitted to reach room temperature before unsealing its package prior to use (see

handling procedures on page 3). This will prevent moisture condensation build up in the solder paste.

APPLICATION:

Formulated for both standard and fine pitch stencil printing, at print speeds of between 25mm/sec (1”/sec)

and 150mm/sec (6”/sec), with stencil thickness of 0.100mm (0.004”) to 0.150mm (0.006”), particularly

when used in conjunction with ALPHA Stencils. Blade pressures should be 0.18-0.27 kg/cm of blade (1.0

-1.5 Ibs/inch), depending upon the print speed. The higher the print speed employed, the higher the

blade pressure that is required. The reflow process window will give high soldering yield with good

cosmetics and minimized rework.

TECHNICAL DATA:

HALOGEN STATUS:

CONTACT INFORMATION: